% Rs. 0.00

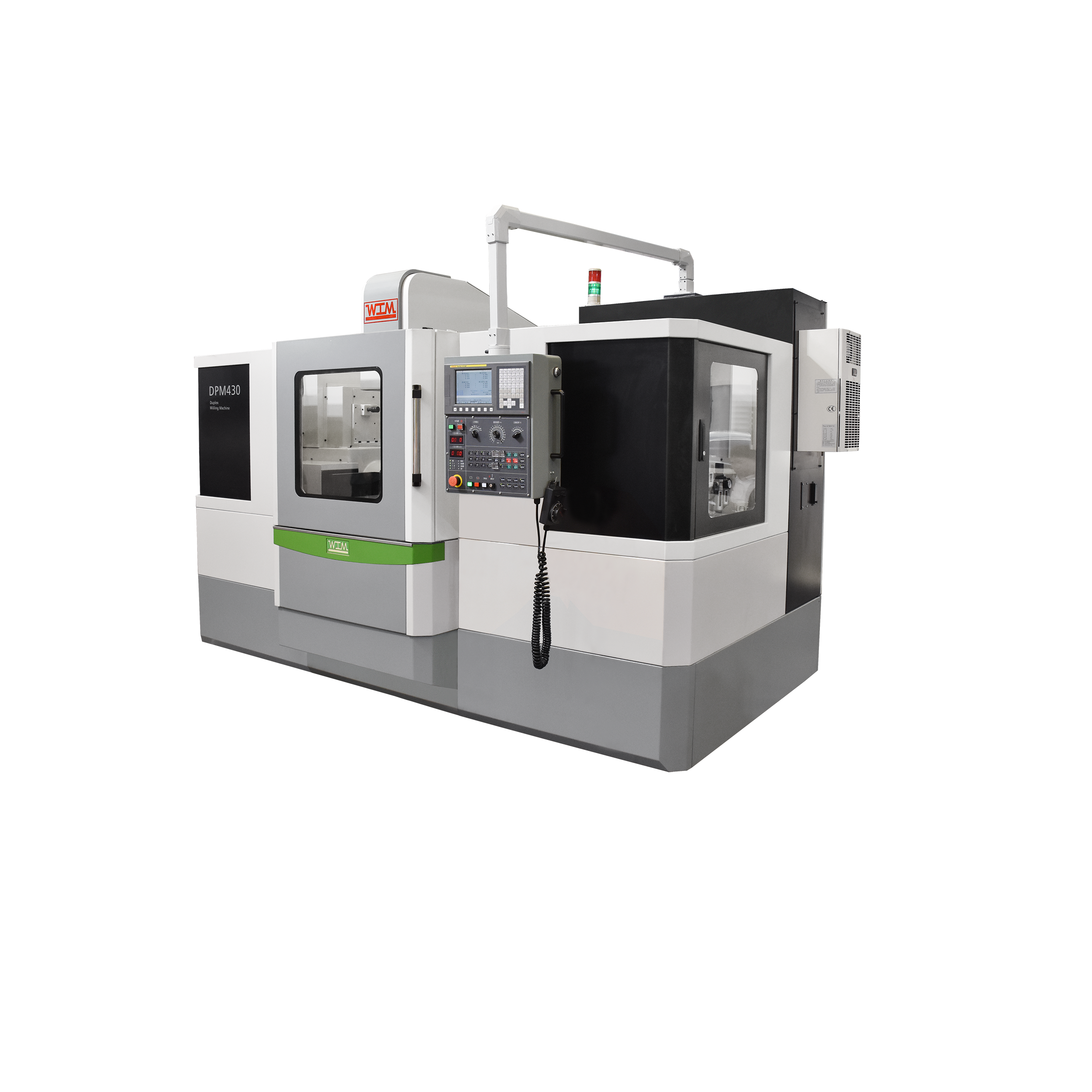

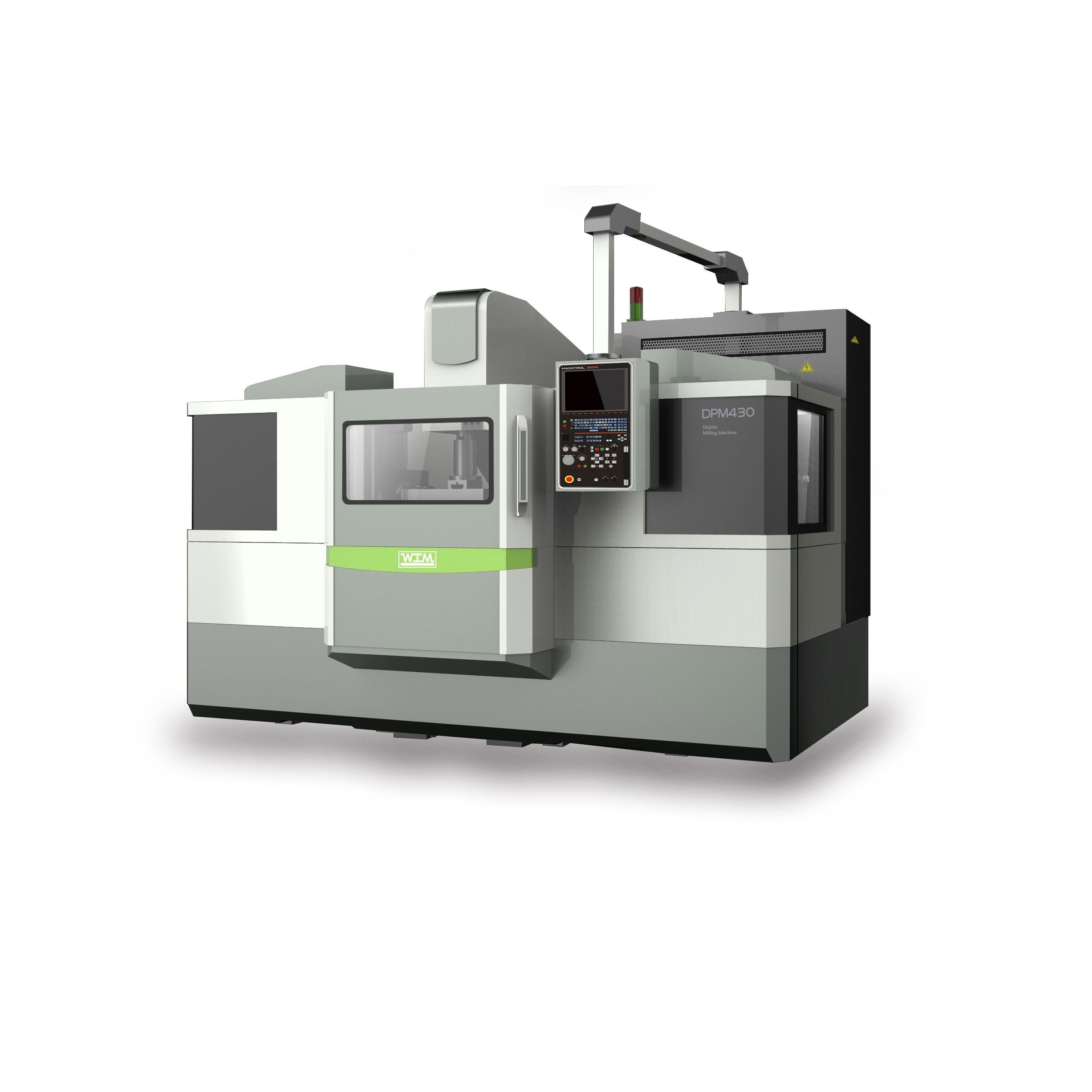

- Brand - WIM

- Type - Milling & Drilling Machine

- Height - 3750 mm

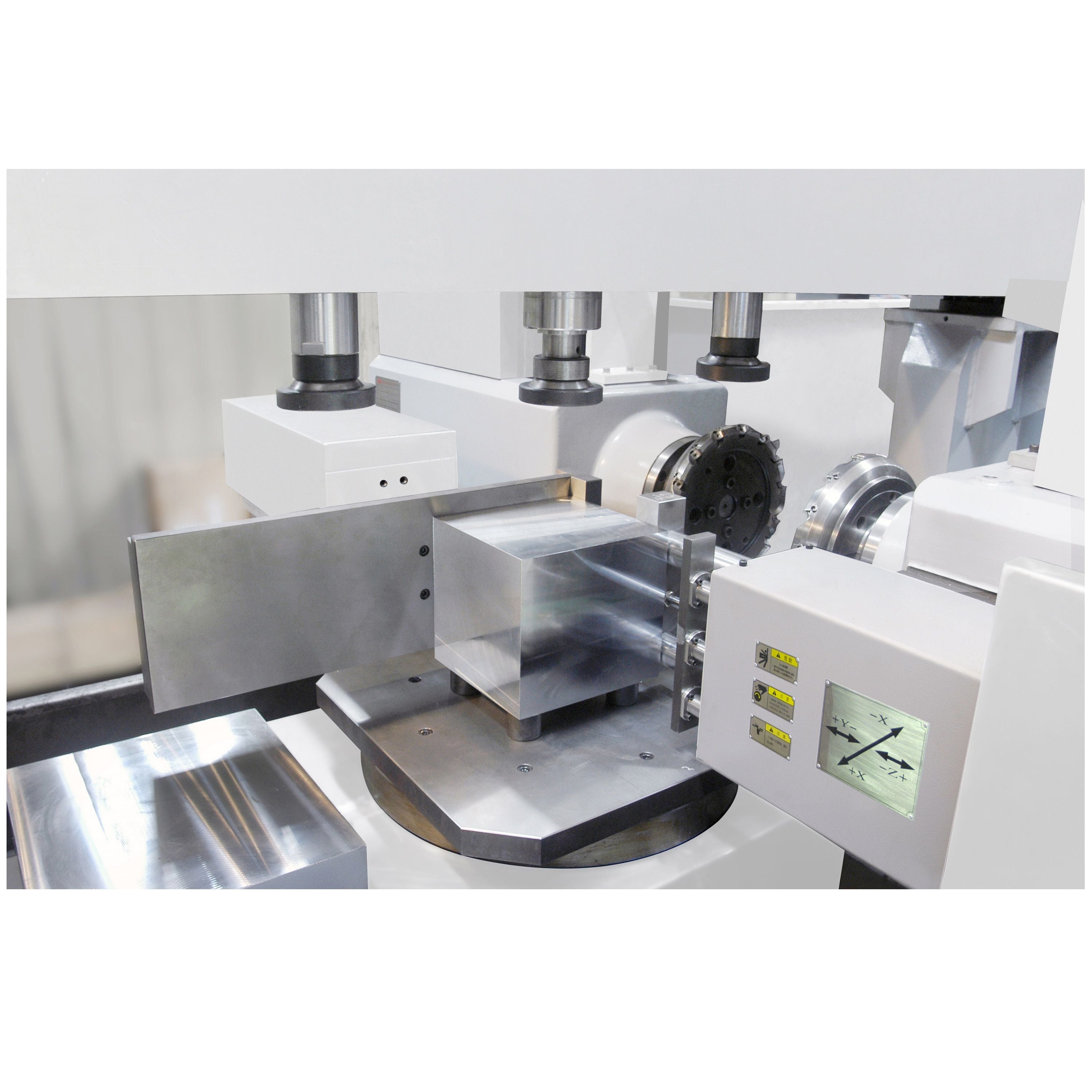

- Size - 1200 x 1000 mm

- Spindle Bore Taper - BT40

- Total Power Requirement - 53 kW

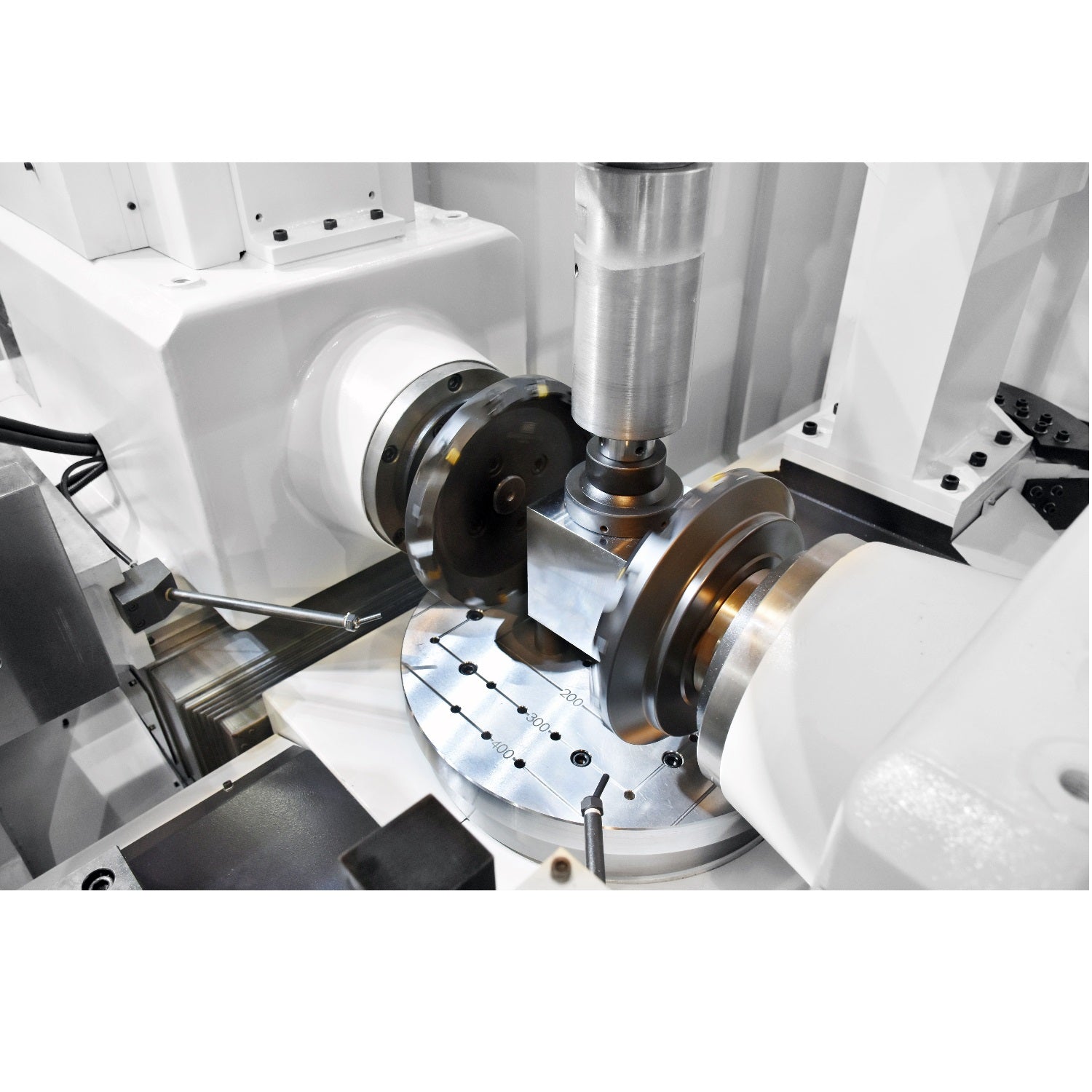

- Table Maximum Rotation Speed (B) - 2 rpm

- RAM Maximum Tilting Speed (A) - 215 degree/min

- Coolant Pressure (Gun Drill) - 2 - 11 Mpa

- A Axis Motor - 20 N.m

- B Axis Motor - 27 N.m

- X Axis Motor - 20 N.m

- Y Axis Motor - 27 N.m

- Z Axis Motor - 27 N.m

- RAM Travel (Y) - 1200 mm

- Max. Spindle Speed - 6000 rpm

- Milling Capacity - 180_cc/min

- Tapping Capacity - M20 x 2.5 mm

- Table Horizontal (X) - 1500 mm

- Column Horizontal (Z) - 500 mm

- Spindle Motor - 15/18.5 (30min)

- RAM Tilting Travel (A) - clockwise 15°, counterclockwise 25°

- Weight - 18000 Kg

Dispatched by |